One-stop-solution for machine vision products.

Mstar Technologies, Inc, as a leading provider of a comprehensive Machine Vision System in China, was founded in March 2012, located in Zhejiangoverseas High-Level Talents Innovation Park. Mstar Technologies, Inc, is a company engaged in the area of development and production of machine vision products including machine vision system, industrial camera, FA lenses, machine vision lightings, infrared thermal cameras and etc..

Ask our Engineers about your application!Do you have an important technical question?Are you looking for the solution for your application?

Six Side Code Reading System

Six Side Code Reading System

Background

Requirement Description:

1. Need to realize the comprehensive and stable identification of the six sides of the package;

2. Need to be compatible with different sizes of barcode recognition;

3. Need to be compatible with one, two-dimensional code read at the same time;

4. Adapt to high package density scenarios, support minimum package spacing of 400mm;

5. 2.2m/s high speed scene code reading.

Technical Requirements:

1. Code reading accuracy: > 98%;

2. Minimum cell width of barcode: 10mil;

3. Bar code length: 60 ≤ x ≤ 122 mm;

4. Package size: 160 * 80 * 10-1000 * 700 * 700;

5. Depth of field requirement: 700mm (Center);

6. Conveyor belt width: 1000mm;

7. Belt speed: 2m / s.

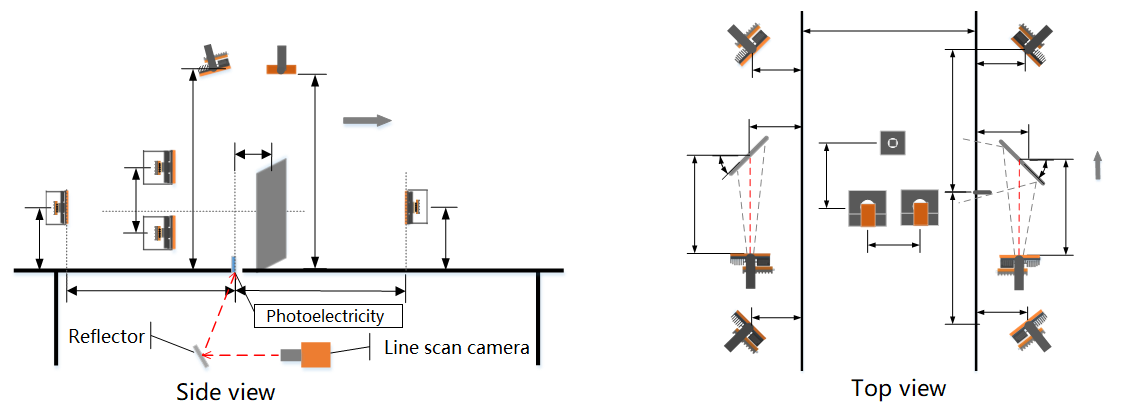

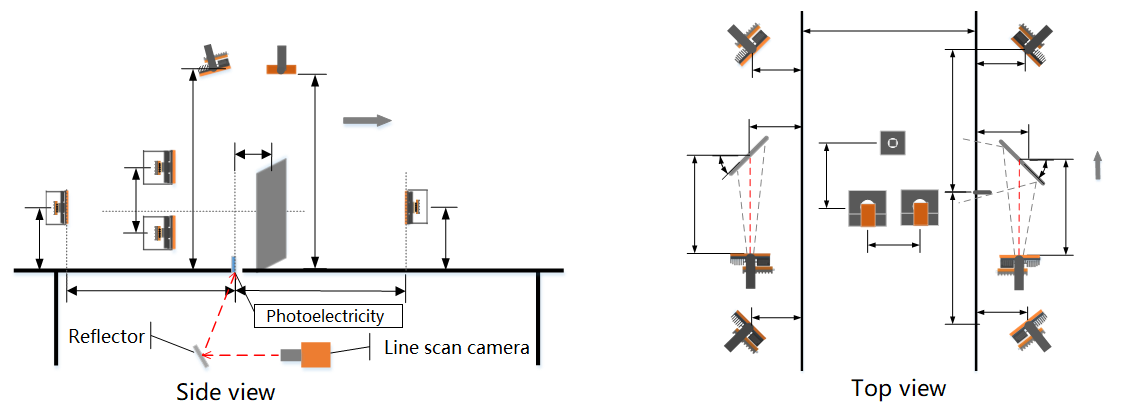

Structure

In the scheme of six side code reading system, large resolution area array cameras (8.9 mp, 12 mp, 20 mp) are provided in the upper, left, right, front and back; 4K / 8K linear array camera is provided at the bottom to realize the Omni-directional code reading of six sides.

Advantages

1. Abundant products and flexible system: flexible combination of area array cameras, selection of appropriate models according to different sites to meet the diversified needs of customers;

2. Rich accessories and complete functions: provide customized mirrors for matching, reduce the working distance of the side camera, and the overall equipment takes up very small space; the bottom surface can adapt to the conveyor belt of different heights, and identify the reflective / film covered barcode stably;

3. Friendly interaction: the code reading platform can be directly connected to multiple intelligent cameras and industrial cameras, with drag and drop scheme design, simple operation, clear interface and perfect functions;

4. The algorithm is superior and robust: the self-developed code reading algorithm has ultra-high code reading rate, strong adaptability to barcode distortion, wrinkle, film, etc., and perfectly matches the large distortion scene of front, back, left and right, as well as high-speed code reading with large resolution on the bottom.

Mstar Technologies, Inc, as a leading provider of a comprehensive Machine Vision System in China, was founded in March 2012, located in Zhejiangoverseas High-Level Talents Innovation Park. Mstar Technologies, Inc, is a company engaged in the area of development and production of machine vision products including machine vision system, industrial camera, FA lenses, machine vision lightings, infrared thermal cameras and etc..