One-stop-solution for machine vision products.

Mstar Technologies, Inc, as a leading provider of a comprehensive Machine Vision System in China, was founded in March 2012, located in Zhejiangoverseas High-Level Talents Innovation Park. Mstar Technologies, Inc, is a company engaged in the area of development and production of machine vision products including machine vision system, industrial camera, FA lenses, machine vision lightings, infrared thermal cameras and etc..

Ask our Engineers about your application!Do you have an important technical question?Are you looking for the solution for your application?

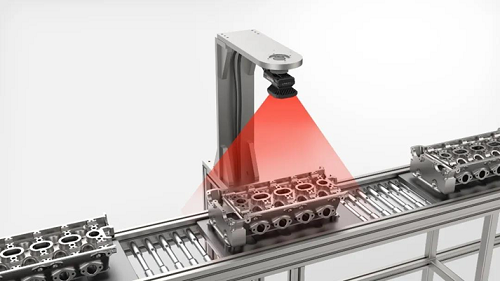

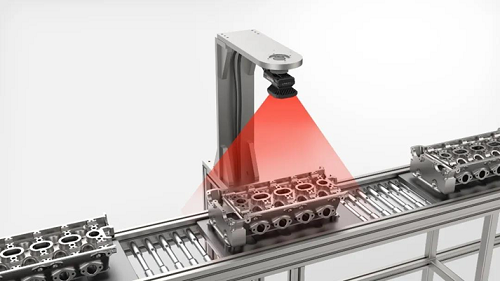

DPM Code Reading of Automobile Parts

DPM Code Reading of Automobile Parts

In the aspect of automobile assembly production, id5000 series code reader is used to solve the traceability of various working conditions. It is compatible with various processes and interference environment to realize high accuracy …

Background

Requirement Description:

1. Working condition: solve the code reading application adapting to various working conditions

2. Process: DPM identification of laser, mechanical printing, inkjet, etc.

3. Environment: considering oil pollution, texture, static area loss, distortion and other interference

Technical requirements:

1. The recognition rate of QR code is up to 99.99%

2. Unit decoding beat < 60ms

Structure

ID5000 / 3000Pro series intelligent code reader is selected for the DPM code reading scheme of automobile components. The product integrates lighting, sensor, lens and decoder. It has excellent recognition performance, defect correction, dirt filtering, distortion correction and intelligent error correction. It has high decoding ability and millisecond positioning algorithm. It does not need external light source, multi-channel sub control and multi-color light source of white, red and blue.

Advantages

1. Integration: lighting, CCD, lens and decoder integration;

2. Accessories: multi-channel sub control, white, red, blue multi-color light source and polarization multi optical accessories to adapt to multiple working conditions;

3. Rating: ISO international general quality rating standard, guiding process management;

4. Alternation: it can be compatible with more working conditions and material differences, and automatically switch parameters;

5. Level: high degree of shell protection, deployment of more severe environment.

Mstar Technologies, Inc, as a leading provider of a comprehensive Machine Vision System in China, was founded in March 2012, located in Zhejiangoverseas High-Level Talents Innovation Park. Mstar Technologies, Inc, is a company engaged in the area of development and production of machine vision products including machine vision system, industrial camera, FA lenses, machine vision lightings, infrared thermal cameras and etc..